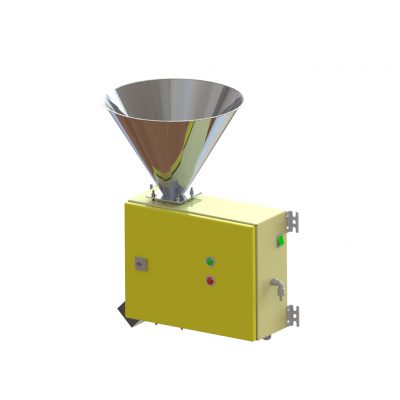

LCS Separators

LCS separators are used for slowly moved material columns. When metal is detected the complete search coil together with the contaminated materials are brought into the reject position pneumatically. During the reject procedure the material inlet is closed by a sluice plate. After metal rejection the sensor is returned to the initial position.

The Hamos LCS is available in three assorted sizes (50, 70 and 100 mm) with maximum sensitivities from approximately 1.0 mm.

Applications

The Hamos LCS (“Last Chance Separator”) series are used especially in plastics processing with slow moving or “stationary” material columns. They offer the last chance of detecting damaging metal parts and removing them fully automatically.

The Hamos LCS is the ideal equipment for metal separation if you recycle:

plastic granulates, ground plastics, plastic recyclate

HS Separators

All HS-Metal separators are designed for gravity fed free flowing products. The materials fall through the shaft of the metal separator. Contingently contained metallic parts are detected electronically. A pneumatic operated ejection flap is activated. The product stream is diverted temporarily, and the metallic part is separated together with a small amount of the product.

Our stocking program contains units with sensitivities from approximately 0.5 mm (steel sphere diameter) and for throughputs up to 23,000 kg per hour.

Applications

Hamos HS electronic all metal separators serve for detection and fully-automatic removal of individually arising metallic contamination in free-falling, free-flowing bulk materials.

The Hamos HS is the ideal equipment for metal separation if you recycle:

plastic granulates, ground plastics, regrinds, powder/dusts, chemicals, pharmaceutical products, recycling materials, wood cuttings, food, feed, other bulk materials.

.

FFS Separators

With the FFS All-Metal separators the products to be demetallized are conveyed through the metal search coil pneumatically. Depending on the kind of transportation (pressure or vacuum system, continuous or intermittent) specially designed rejection mechanisms are used. When a metallic particle is detected the rejection flap inside the unit is opened. The product stream is diverted temporarily, and the metallic part is sent into the separation container together with a small amount of product. The conveying pressure is retained during the entire separation procedure.

Units for tube diameter from 38 mm [1 ½”] (max. sensitivity approximately 0.5 mm) up to 100 mm [4”] (max. sensitivity approximately 1.2 mm) are offered.

Applications

The Hamos FFS Series recognize and remove metal particles from bulk materials that are transported in vacuum and pressure conveying lines.

The Hamos FFS is the ideal equipment for metal separation if you recycle:

plastic granulates, ground plastics, regrind, powder/dusts, chemicals, pharmaceutical products, recycling materials, food, feed, other bulk materials.